Micromanufacturing: Precision at the Microscale

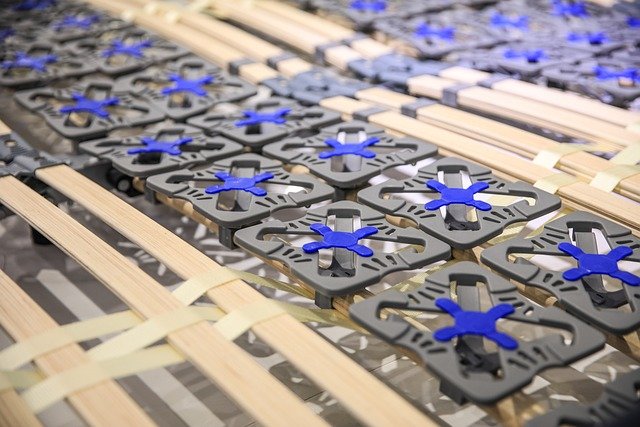

Revolutionizing production processes, micromanufacturing is reshaping industrial landscapes. This cutting-edge approach to manufacturing at the microscale is opening new frontiers in product design, material efficiency, and operational flexibility. As industries seek to miniaturize components and enhance precision, micromanufacturing emerges as a game-changing solution with far-reaching implications for business strategy and industrial innovation.

Historical Context and Industry Development

The journey of micromanufacturing began in the 1960s with the rise of microelectronics. As the demand for smaller, more powerful electronic devices grew, so did the need for manufacturing processes capable of producing microscale components. The semiconductor industry pioneered many of the techniques that would later form the foundation of micromanufacturing, such as photolithography and etching.

In the 1980s and 1990s, micromanufacturing techniques began to diversify beyond electronics. The emergence of microelectromechanical systems (MEMS) marked a significant milestone, enabling the production of tiny sensors and actuators. This expansion opened up new possibilities in fields like automotive, aerospace, and medical device manufacturing.

Current Trends and Applications

Today, micromanufacturing is at the forefront of industrial innovation, driven by the increasing demand for miniaturization across various sectors. In the medical field, micromanufactured devices are revolutionizing diagnostics and drug delivery systems. For instance, lab-on-a-chip devices can perform complex medical tests using minimal sample volumes, offering faster and more cost-effective diagnostics.

In the automotive and aerospace industries, micromanufacturing is enabling the production of lighter, more efficient components. Microfluidic devices, for example, are being used to create more precise fuel injection systems, improving engine performance and reducing emissions.

The consumer electronics sector continues to push the boundaries of micromanufacturing, with ever-smaller components being integrated into smartphones, wearables, and other devices. This trend is not only driving product innovation but also reshaping supply chains and manufacturing strategies.

Technological Advancements Driving Micromanufacturing

Several key technologies are propelling the growth of micromanufacturing. Additive manufacturing, or 3D printing, at the microscale is opening up new possibilities for complex geometries and customized production. Two-photon polymerization, for instance, allows for the creation of intricate 3D structures with sub-micron resolution.

Laser micromachining has become increasingly sophisticated, enabling the precise removal of material at the microscale. This technology is particularly valuable in the production of medical devices and aerospace components where precision is paramount.

Advances in materials science are also playing a crucial role. The development of new nanomaterials and smart materials is expanding the range of properties achievable at the microscale, leading to innovative applications in fields like energy storage and biomedical engineering.

Impact on Business Strategy and Operations

The rise of micromanufacturing is compelling businesses to rethink their production strategies. The ability to produce smaller, more precise components often translates to reduced material costs and energy consumption. This efficiency can lead to significant cost savings and improved sustainability metrics, aligning with growing environmental concerns.

Micromanufacturing also enables greater product customization and faster iteration cycles. This flexibility is particularly valuable in industries with rapidly evolving consumer demands or strict regulatory requirements. Companies that can quickly adapt their micromanufacturing processes to produce new or modified products gain a substantial competitive advantage.

However, the transition to micromanufacturing is not without challenges. The high initial investment in specialized equipment and the need for highly skilled personnel can be significant barriers to entry. Additionally, quality control at the microscale requires advanced metrology techniques, adding complexity to the manufacturing process.

Future Prospects and Industry Outlook

As micromanufacturing continues to evolve, its integration with other emerging technologies promises to unlock new possibilities. The convergence of micromanufacturing with artificial intelligence and machine learning, for instance, could lead to self-optimizing production systems capable of unprecedented precision and efficiency.

The potential for micromanufacturing to enable localized, on-demand production of small components could disrupt traditional supply chain models. This shift might lead to more resilient and agile manufacturing ecosystems, better equipped to handle supply chain disruptions.

Key Considerations for Implementing Micromanufacturing

• Assess the potential impact on your product portfolio and identify areas where micromanufacturing could offer significant benefits

• Invest in workforce development to build the specialized skills required for micromanufacturing operations

• Consider partnerships with research institutions or specialized manufacturers to access cutting-edge micromanufacturing technologies

• Evaluate the total cost of ownership, including equipment, materials, and ongoing operational expenses

• Develop robust quality control processes tailored to the unique challenges of microscale production

As industries continue to push the boundaries of what’s possible at the microscale, micromanufacturing stands poised to play an increasingly pivotal role in shaping the future of production. By enabling the creation of smaller, more precise, and more complex components, this technology is not just miniaturizing products—it’s opening up entirely new realms of possibility. For businesses across sectors, understanding and leveraging the potential of micromanufacturing could be the key to unlocking new levels of innovation, efficiency, and competitive advantage in the years to come.